Providing Innovative and Sustainable Solutions in Energy Efficient Surface Aerators

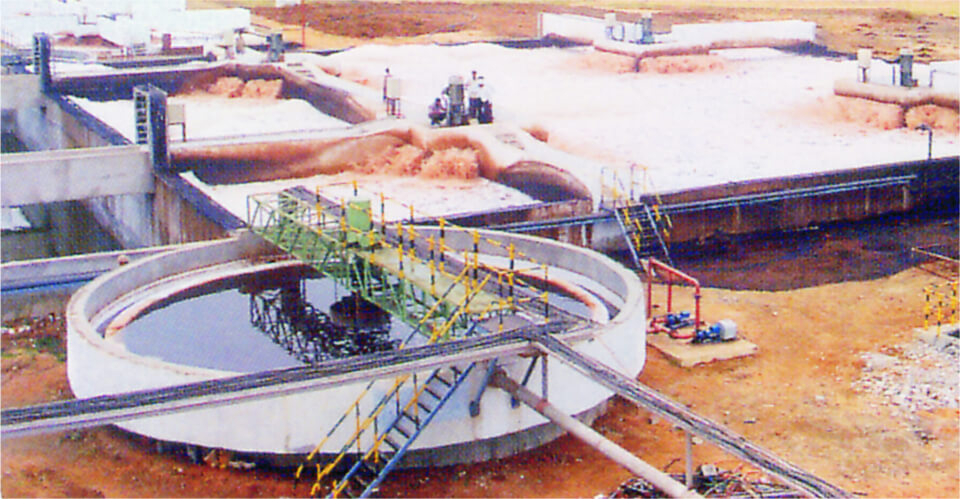

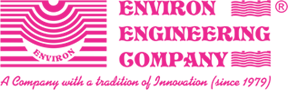

Clarifiers, Thickners, Clariflocculators

Environ High Torque Central Drive Clarifiers, Clariflocculators, High Rated Solid Contact Clarifiers (HRSCC) & Thickners

Clarifier

Environ Clarifiers, described hereunder, are for chemical effluents, various types of industrial processing & even metallurgical processing, where the efficient separation of solids from liquids is the ‘NEED’. Efficient separation of suspended solids or sedimentation is an important and essential aspect in effluent treatment since it not only reduces considerably suspended solids loading, but also helps in reducing the COD / BOD loading, thereby contributing to reducing the sizing of subsequent process viz. that of Biological treatment, etc.

Thus, Clarification / Sedimentation, the process to remove suspended solids, is economical and has become an essential part of effluent treatment plants and raw water treatment plants. Suspended solids removal up to 70% and settleable solids removal up to 90% to 98% and COD removal as high as up to 40% are achievable with the proper design of the clarifier unit.

The process is pure of gravity-separation. This is achieved by the reduction in velocity of the fluid and nearly 180o change in the direction of the flow. The separate solids would flow downward and settle on the tapered floor.

The slow-moving scraper mechanism having scraper arms with neoprene rubber / PP / HDPE / Brass squeegees scrapes the floor and brings the settled sludge (suspended solids) to the central sludge well. The velocity of the movement of scraper arms, squeegees is designed in such a way that the sedimentation process is not distributed at all.

Comparision Between End Drive / Centre Drive Clarifiers

There are two basic types of the clarifier mechanisms which are manufactured.

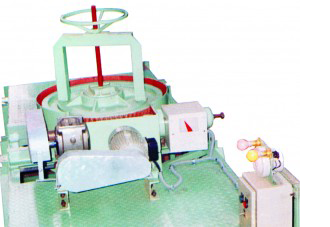

Even though we manufacture both types of Clarifiers at our ENVIRON workshop (having 40,000 sq.ft. area), ENVIRON recommend CENTRE DRIVE Clarifiers to their valued customers & clients for the following reasons :

Having more than Thirty years of manufacturing experience in effluent treatment plant machinery and having full-fledged Research & Development Department attached with hydraulic testing facilities up to 150 HP Aerators & having manufacturing facilities of total 40,000 sq.ft. area, we have developed & incorporated following essential cum efficient features in ENVIRON Clarifiers.

Special Features

Environ Clarifiers Without Bottom Sludge Withdrawal Pipe

For the first time in India, we have Developed & Introduce for minimal maintenance, the ENVIRON Clarifiers without bottom sludge withdrawal pipe. The sludge at 5 to 10mt. total head (pressure) can be obtained at the end of the platform simply by pipe flange connection, this can be taken either to sludge drying beds &/or to aeration tanks for activated sludge plants.

Advantages

Clariflocculator

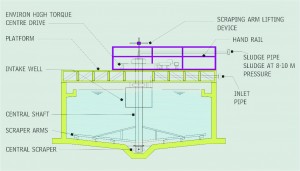

General arrangement of Clariflocculator

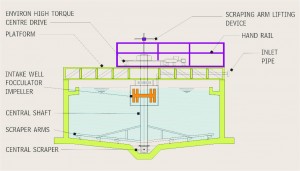

General arrangement of Clarifier

Clariflocculators are generally used for chemical primary treatment for effluent. Instead of separate flocculation & clarification, Clariflocculator is generally used. This results in economical and faster installation of primary treatment. Our Clariflocculators are having high torque center drive with a sludge arm lifting device. We are the only manufacturers to provide this feature as standard. The main feature of Clariflocculator, unlike others, is concentric paddle type Flocculator mechanism which creates the flocs throughout the flocculation zone.

Skimming Device

The skimming mechanism, if required by the client or required for particular applications, can be provided by us. Generally, this mechanism is required to remove floating debris, solids, which floats on effluent surface. It compromises of 1) Rotating Skimmer 2) Scum Scraper 3) Scum Box. Neoprene Rubber wipers are generally provided. The scum scraper collects the scum and drops it in scum box, which is connected to withdrawal piping. A scum skimming arm, supported on one of the scrapper arm, is provided for removal of floating debris, solids. The collected scum is pushed by a level-loaded or spring loaded scraper into a scum box. Through this scum box the scum drains off the paddle and pipe. Thus floating scum is taken out from the clarifier.